Bollore Logistics (18 May 2021) - Problem Statement (2)

Alternative transport modes, fuels, packing materials & end-to-end services.

For startups with Technology Readiness Levels of 4 & above.

Alternative transport modes, fuels, packing materials & end-to-end services.

For startups with Technology Readiness Levels of 4 & above.

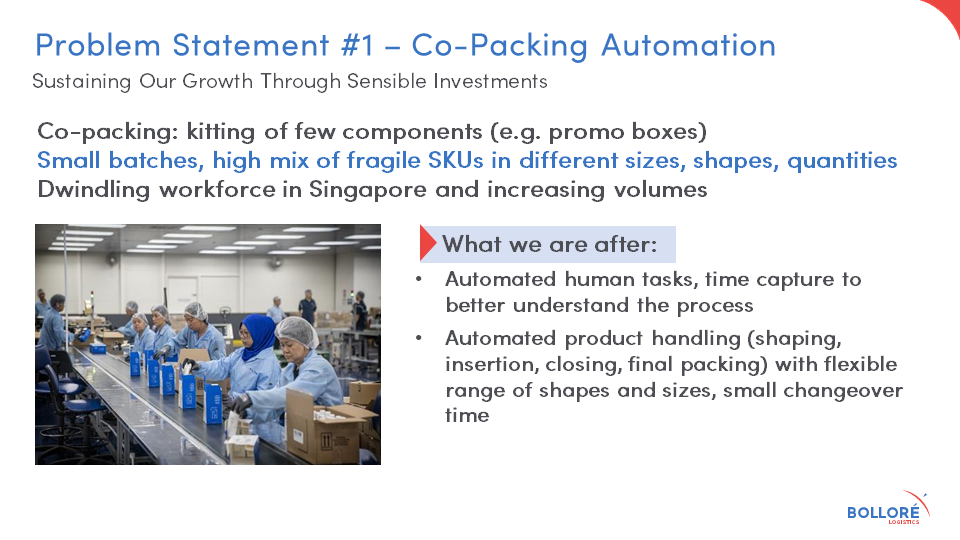

Automated human tasks, and automated product handling with small changeover time.

For startups with Technology Readiness Levels of 4 & above.

CP Foods Thailand’s business units produce around 270,000 tonnes of animal manure every year which is discarded into landfills. These waste products often consist of a mixture of manure and rice husks.

Objectives:

CP Foods Thailand is looking to identify potential solutions to convert these waste products into value and reduce their carbon footprint.

One of the potential solutions that CP Food Thailand would like to explore would be to convert these waste products into organic fertilizers or into renewable fuels. But they are also open to all other ideas.

Working Model:

After partnering with selected startups, CPF Thailand will test solutions and co-develop a prototype or a POC before testing the solution at scale in a real environment to measure its business impact.

As part of the Capitaland Master Sustainability Plan, The Ascott is committed to reducing water and energy use over the next few years. There is an increasing need for the group to find solutions that can address the needs of the properties that Ascott operates globally. The properties range from Serviced Residences, Rental Housing, Hotels, Senior Living Estates and Student Accommodations.

Objectives:

To find a solution that will help Ascott-operated properties reduce water and/or energy usage.

Working Model:

If possible, a charging model based on a revenue share where the vendor takes a cut out of the savings made from the utility bill. Allowing properties to implement easily without incurring large upfront CAPEX.

As part of the Capitaland Master Sustainability Plan, Ascott is committed to reducing waste over the next few years. There is an increasing need for the group to find solutions that can address the needs of the properties that Ascott operates globally. The properties range from Serviced Residences, Rental Housing, Hotels, Senior Living Estates and Student Accommodations.

Objectives:

Because each Ascott property is on average 200 rooms, and does not operate F&B, the scale of the property does not justify the purchase of expensive equipment that costs tens of thousands of dollars.

The Ascott is looking for a solution that will help Ascott-operated properties with at least two out of four of the following:

Working Model:

The solution should be lightweight and if possible, offered on the as-a-service model.

Objectives:

To identify opportunities within the global availability of more than 1 billion tonnes of agrifood by-products (such as husks, hulls, bran, germ, etc) being under-valorised in terms of nutrients or components and going to waste.

Working Model:

Bühler group has identified three key opportunity areas

CPF Thailand is looking for a renewable energy solution for their farms and factories. The solution has to be able to generate or store enough energy to power the farm and factory for 24 hours a day with a sound financial feasibility. This aligns with the group’s holding policy to help CP Group achieve carbon neutrality.

Objectives:

To identify a renewable energy solution to power their farms and factories.

CPF Thailand has identified the following potential solutions to their problem but is open to all other ideas.

Working Model:

After partnering with selected startups, CPF Thailand will test solutions and co-develop a prototype or a POC before testing the solution at scale in a real environment to measure its business impact.

Currently, TES receives a large amount of electrical and electronic equipment in their original packing in pallets or boxes. These pallets need to be unpacked and sorted into unique waste streams.

Some unique products will then have to be further de-manufactured, disassembled or dismantled into their individual components materials which may involve the removal of casings, screws, etc.

The current process is manual and labour intensive, and therefore time consuming, costly and error prone. The effectiveness and efficiency are also currently heavily dependent on the competence and capability of individuals.

Objectives:

TES would like to explore automating whole or part of the current process to improve efficiency. As there is a broad range of non-homogenous packaging, materials and products received, they are looking to define a standard process for this.

TES has identified some potential solutions to this problem.

Currently TES receives a large amount of non-homogenous lithium-ion mobile phone batteries that need to be discharged prior to shredding. Non-discharged lithium-ion batteries represent a significant combustion risk if they are damaged or tampered. A damaged battery cell can go into thermal runaway, producing enough heat to cause adjacent battery cells to also go into thermal runaway. This produces a fire that repeatedly flares up as each battery cell in turn ruptures and releases its contents. These types of fires are extremely dangerous, life-threatening, and difficult to extinguish.

The broad range of non-homogenous lithium-ion batteries received also makes it difficult to define a standard process.

Objectives:

TES would like to explore the possibility of automating this process.

There are efficiency and risk mitigation benefits to be gained by establishing a timely, low risk and automated process. Some of the questions to be posed include:

The grading of equipment (e.g., mobile phone, laptops, desktops, monitors etc) is an important step in our process to establish the condition prior to sale. The grade of the equipment is based on both function and form/condition.

Objectives:

TES would like to explore the possibility of automating whole or part of the current process. Some of the questions to be posed include: