Getting hands on in a hardware startup

Mon, 02/19/2024 - 12:00

For these undergraduates from the Singapore University of Technology and Design (SUTD), a fruitful internship meant working somewhere they could apply their technical knowledge to solve real-world challenges. Not only did their stint at local hardware startup Fabrica AI allow them the autonomy to pursue their own projects, but it also exposed them to the entire engineering product development cycle and to like-minded individuals in the industry who helped shape their perspectives and goals as budding engineers and makers.

Ho Soon Yee is an avid tinkerer. At 19, he co-designed a low-cost, muscle-activated glove to help stroke victims relearn how to grasp their hands. Two years later, he was building drones from scratch, and competing in the annual Singapore Amazing Flying Machine Competition.

So when it was time to do an internship, the Electronics and Electrical Engineering student at the Singapore University of Technology and Design (SUTD) wanted to work in a “real-world” startup where he could put his skills to the test.

Soon Yee (left) at the Singapore Amazing Flying Machine Competition 2021 where he clinched the top prize in his category. Soon Yee (left) at the Singapore Amazing Flying Machine Competition 2021 where he clinched the top prize in his category.

In August 2023, he began a three-month apprenticeship at Fabrica AI. The Singapore startup aims to shorten the time taken to create robots for specific tasks from a few years to a matter of days by automatically generating, iterating and testing hardware designs through reinforcement learning.

“I wanted an apprenticeship where I could do projects in line with my interests and areas of growth that I want to pursue, which are in electronics,” said Soon Yee, 24, who joined Fabrica AI’s electronics design team via SGInnovate’s Summation Programme for Talent.

The experience convinced him to deepen his involvement and pursue his interest in electrical engineering. He had the chance to shape actual projects, and found the experience was so rewarding that he opted to extend his stint by a month.

Watch: The Apprentices Behind The Scenes In A Hardware Startup

From the classroom to the real world

At Fabrica AI, Soon Yee relished the chance to hone his skills in robotics and engineering – especially with easy access to specialised equipment such as oscilloscopes, multimeters, and function generators.

“I could use these facilities to gain experience, before gaining intuition on how to design (robots) properly,” said Soon Yee, who is now in his third year at SUTD where he specialises in Engineering Product Development.

Soon Yee making adjustments to the printed circuit board (PCB), or as he calls it, the ”brains” of the robot.

In his first few weeks at the startup, along with teammates, Soon Yee was tasked to identify where improvements could be made to version four of the company’s first product, a tile-grouting robot that boosts productivity by five times.

This gave them a fuller understanding of the robot’s basic components, motors, and architecture.

One key problem they faced was “electrical noise”, which would corrupt data readings between sensors, Soon Yee said. This would then cause the robot to misinterpret commands from the user, and could result in unpredictable behaviour.

“The robot might be supposed to move towards the wall, but might either stop before reaching the wall or crash into it,” he explained.

Electrical noise also puts additional stress on other components that are exposed to it, he added. As a result, the lifespan of other components might be reduced, causing the robot to fail sooner.

After a series of discussions with his mentor, Soon Yee was put in charge of improving the robot’s printed circuit board (PCB), its main control system.

Along the way, he sought advice from the startup’s external consultants who taught him to approach the problem from a different perspective. For instance, they suggested that the PCB’s wire harness – a system that organises wires and cables together – could be a potential cause of the electrical noise.

A close up of the inside of the grouting robot.

“I was not even thinking about that,” Soon Yee confessed. Following their advice, he designed a new harness to group wires of different signals together.

After a series of tests, he was able to reduce the noise by a significant 50 per cent. The latest iteration of his designs has successfully reduced noise levels by four times and has been integrated into the newest version of the robot.

Through this, he realised that theoretical knowledge alone would not provide him with all the answers in the workplace.

“I thought I had a decent understanding from lessons in school, but I realised there are areas I have no idea about,” he added.

Ho Soon YeeTo Jakub, we should take time to address the root cause of the problem. There is a shift in mentality that he has imparted to me to think more long-term. We are not just putting out fires, but also putting things in place so solutions will be smoother in the long run.

Teamwork makes the dream work

The startup’s open-office layout and fast-paced culture encourage collaboration between different teams. It also has a flat hierarchy, which gave Soon Yee a greater sense of ownership over projects.

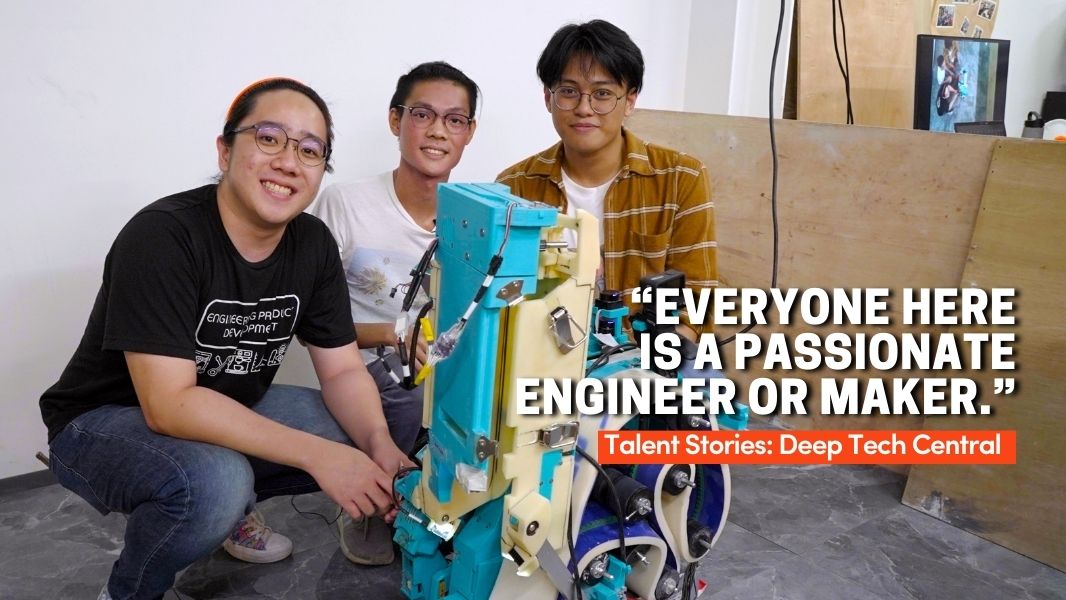

During his three-month stint, he worked closely with fellow SUTD apprentices, Jalen Mateo and Joshua Nick Tan, to fine-tune the mechanics of the firm’s robot.

Although they belong to different teams, they learn from each other daily.

The three apprentices worked closely together on improving Fabrica AI’s grouting robot.

Joshua, who worked on the mechanical team, often listens in on Soon Yee’s discussions about electronics with his mentor, co-founder and CEO Jakub Suchánek. “It is like listening to or watching a lecture online while you do your work,” he quipped.

Working with Joshua – who has a rich background in computer-aided design software – has also helped Soon Yee and Jalen understand why a design is done a certain way.

“The apprenticeship is designed to bring out the best in each apprentice,” said Jakub. “It is based on their skills and what they are interested in.”

Jakub Suchánek and Nelson Ng (black T-shirt), who are both mentors to apprentices, in an informal meeting at Fabrica AI’s office.

Under his guidance, Soon Yee has gained invaluable problem-solving skills. Now, he does not approach an issue blindly, but first considers the root of the problem.

“To Jakub, we should take time to address the root cause of the problem. There is a shift in mentality that he has imparted to me to think more long-term. We are not just putting out fires, but also putting things in place so solutions will be smoother in the long run,” he added.

Soon Yee’s apprenticeship was just the tip of the iceberg for the young apprentice. The company offered him a full-time role to see his project through and experience more of what the hardware startup has to offer. He will complete the grouting robot’s fifth prototype before returning to school.

“This process is very exciting for me. I want to be a part of it,” he said.

Unlock your potential with SGInnovate’s talent programmes here.

Trending Posts

- From satellites to startups, Singapore’s space sector is pushing new frontiers

- How leaders should rethink cybersecurity strategy

- How to Future-Proof a Career in Deep Tech? Start here.

- The future of fusion energy: What will it take to bring the power of the stars to earth?

- Keeping satellites safe: How CYSAT Asia 2026 is tackling space cybersecurity