Why XOdian’s industrial exoskeletons are the future of workplace safety and productivity

Wed, 06/28/2023 - 12:00

A Singapore team is creating innovative wearable exoskeletons that can take heavy loads off human workers – preventing injury while boosting performance.

Across the globe, work-related musculoskeletal disorders (MSDs) are both common and costly. In the US, for example, data from the Bureau of Labor Statistics reveals that MSDs – characterised by injuries to joints, muscles, tendons and other soft tissues – are the single largest category of workplace injury. They are also responsible for almost 30 per cent of workers’ compensation costs every year.

It’s a similar story in most industrial settings everywhere, presenting a global challenge for industry that researchers at National University of Singapore (NUS) are determined to solve. Since 2020, an NUS team of engineers and computer scientists in the Department of Biomedical Engineering has been building two robotic exoskeletons with different target points – the back and shoulders. These powered mechanical frames wrap round workers’ backs and shoulders to help alleviate the physical stresses of heavy and repetitive work.

“Our shoulder and back devices can reduce muscle strain by 40 per cent in the lower back and shoulders when a worker lifts heavy objects, which can help to prevent injuries while also boosting performance,” explains team leader Professor Yu Haoyong. “Our technology is especially timely because with more societies facing the challenge of an ageing population, we need to start protecting our workers against injury when they are young.”

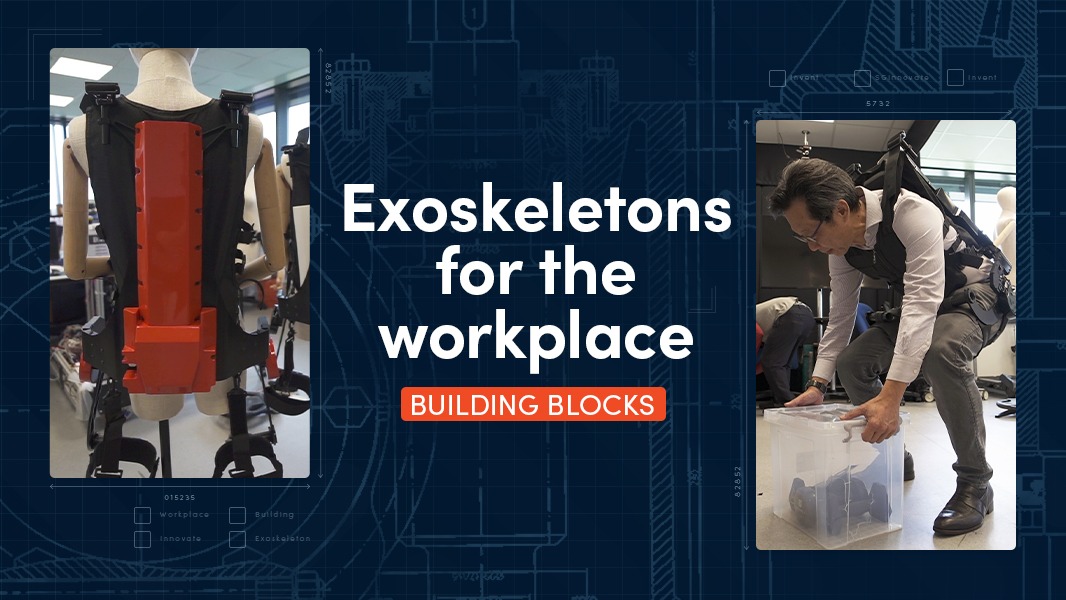

SGInnovate’s CEO Dr Lim Jui wearing XOdian’s back exoskeleton to lift a heavy box.

Today, the team – which calls itself XOdian (Exoskeleton Guardian) – is seeking ways to make its solutions commercially available, at scale and at an affordable cost. But how does XOdian’s technology work, and what sets it apart from other such devices already available on the market?

Technology to help prevent work-related MSDs

Current devices from XOdian utilise sensors and model-based controls to best respond to users.

“Let’s say an engineer wearing our shoulder device is lying on a railway track and needs to lift a heavy drill into position as they repair the undercarriage of a train,” Professor Yu suggests. “As they raise their arm, sensors detect the movement and engage a system of motorised actuators to give the wearer more support. They’ll perform the movement feeling like they’re simply resting their arm on a comfortable base.”

Research Fellow Ashwin Narayan demonstrates how the shoulder exoskeleton works.

The XOdian back device works in a similar way, as the professor explains. “Imagine a baggage handler wearing our structure needs to lift heavy cases onto a trolley. When they bend down, our device will apply torque at their hip via an actuator that creates a countermovement. That way, they can lift any weight up from the ground more easily and hold it in position.”

The team is working to include a built-in artificial intelligence (AI) computer system that uses sensor data to help guide their use.

Delivering a unique take on existing formats

Exoskeletons are not new, but many early devices were focused on military and medical applications. In developing its XOdian technology, the 12-strong NUS team has been working to address some of the design challenges often associated with deploying exoskeletons in industrial settings.

Those challenges include design. Many existing models on the market are ‘passive’ exoskeletons, reliant on springs that the wearer must use energy to compress. By contrast, XOdian’s ‘active’ devices deploy motorised components powered by a small, lightweight battery unit that can run for up to eight hours on a single charge.

XOdian’s devices have one actuator placed at the back of the suit which reduces the weight of the device.

Then there is the learning curve associated with exoskeleton use. Until recently, exoskeletons improved the wearer’s capabilities but often slowed their movements. Users needed training to move the exoskeleton in the desired way.

Another issue is comfort and wearability. “In contrast with other ‘active’ exoskeletons in the market, XOdian’s devices only use a single actuator,” says Professor Yu. “That makes our devices lighter and more flexible – and unique – compared to other brands.”

Making the leap from lab to market

XOdian’s journey towards becoming a company began in 2022 when SGInnovate’s venture building arm approached Professor Yu with a proposal to co-create his team’s solution.

“We’re always on the lookout for innovative research being conducted within Singapore’s universities and research labs that has the potential to provide impactful and scalable answers to global challenges,” explains Suchitra Narayan, Director, Venture Building, SGInnovate. “Once we find something, we work with the research teams to help create commercially viable, venture-fundable businesses.”

“That can mean coming in early in the research stage if we do spot a potential winner – as was the case with XOdian. Then, once we decide there is business viability, we’ll work with the team to license their IP from the appropriate body. We’ll also help them build a business plan they can use to apply for government funding to develop their tech readiness over a two-year period. That typically involves building a prototype and trialling it with one or two customers.”

During this time, the venture building team will also offer business development guidance in areas such as business planning and scaling growth. Sometimes, that can lead to radical shifts in commercial strategy. As Narayan explains, the XOdian team was initially interested in exploring the market for physiotherapy rehabilitation solutions. SGInnovate raised the possibility that the industrial space might be more promising.

“Large-volume sales transactions are not typical with rehab robotics, so it can be really tricky for a startup to succeed in this space,” says Narayan.

Together, the teams decided to focus their energy on producing exoskeletons for workplace settings instead. In Narayan’s words: “It takes many heads and skills coming together to build a viable business. People from totally different industries can add fresh perspectives to say, ‘What about doing this instead?’ And your mind can be blown.”

Harnessing team spirit to inspire success

Today, with ongoing support from SGInnovate’s venture building team, the NUS team is looking to launch XOdian as a company and take its products to market.

That means continuing to work with Narayan’s team to develop an ecosystem of partners in different industry sectors, and build proofs of concept that XOdian can continue to test.

NUS’ XOdian team with the team from SGInnovate. Director of Venture Building Suchitra Narayan (second row, 3rd from left) and Professor Yu Haoyong (second row, 2nd from right).

Most recently, the team has trialled its devices with baggage handlers at Singapore’s Changi Airport and with chemical plant workers tasked with unloading raw materials. “We’re measuring muscle activity and oxygen consumption levels in people doing the same task both with and without the device to gauge how effectively it can reduce fatigue in different settings,” Professor Yu explains.

In the professor’s view, SGInnovate’s ongoing support has been critical. “Looking back, I’d say doing the research is the easy part,” he says. “Going for commercialisation has been quite an intense journey as it involves so many skills that we as academics were not familiar with, including the ability to highlight to investors that there is strong market need.”

One area where Professor Yu hasn’t needed support is team motivation. “We’ve been working on this project consistently together over several years now, and we remain as passionately committed to it as ever,” he says. “We know that our technology can have a positive impact on workers’ long-term health and productivity, so we’re just very excited to see it through.”

Learn more about Singapore’s fast-growing Deep Tech community and the startups that SGInnovate supports.

Trending Posts

- As space cybersecurity lifts off, talent and investment are key fuels

- The future of building inspections can’t stay manual. Meet the startup changing that.

- From satellites to startups, Singapore’s space sector is pushing new frontiers

- How leaders should rethink cybersecurity strategy

- How to Future-Proof a Career in Deep Tech? Start here.